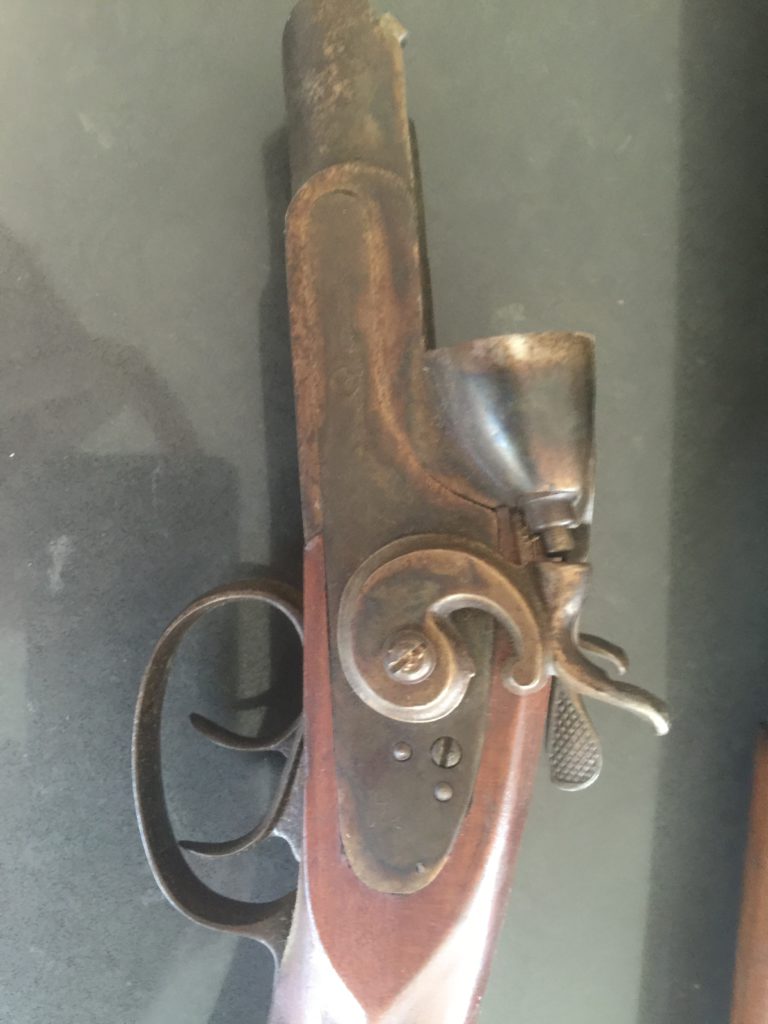

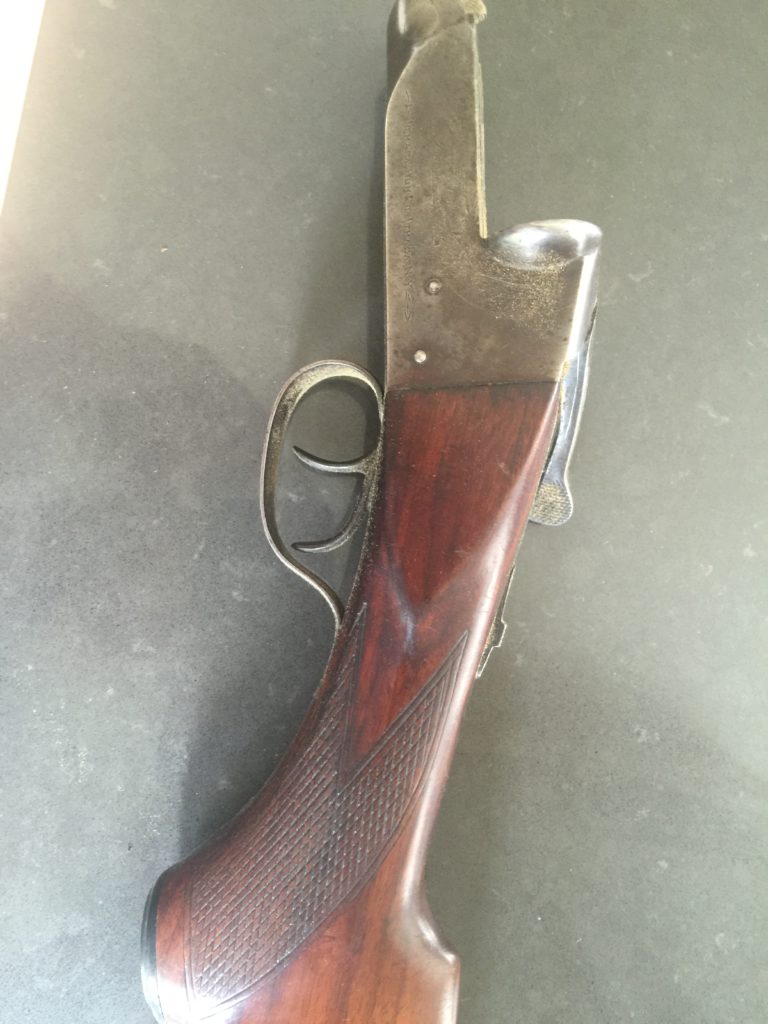

It’s been FIVE YEARS since I dropped these family heirlooms off to be completely restored – functionally and aesthetically. In scope:

- Restored all wood

- Replaced all worn springs,

- ensured bore alignment

- Replaced all trigger assembly components

- Replaced & restored buttplates,

- Cerakoted barrels – this is the only thing that’s not 100% restored to original condition

and most importantly, and most time-consuming:

…… re-case hardening the steel

“The traditional method of applying the carbon to the surface of the iron involved packing the iron in a mixture of ground bone and charcoal or a combination of leather, hooves, salt and urine, all inside a well-sealed box. This carburizing package is then heated to a high temperature but still under the melting point of the iron and left at that temperature for a length of time. The longer the package is held at the high temperature, the deeper the carbon will diffuse into the surface. Different depths of hardening are desirable for different purposes: sharp tools need deep hardening to allow grinding and resharpening without exposing the soft core, while machine parts like gears might need only shallow hardening for increased wear resistance.” – Wikipedia.

In our case, there was no one in the Pacific Northwest that knew how craftsmen of previous generations did this, so we had to send the shotguns out to the University of North Dakota, where apparently there is One_Guy who still knows the craft.

Here are the before & after pics: